ZERO DOWN TIME

When a machine is down, time is money.

That’s why so many have us on speed dial.

We offer 24/7/365 E-Service.

CALL US!

You won’t get a voicemail, you get a person, a technician, an engineer.

We will get you up and running again, fast.

Keep the Lights On,

The Wheels Turning,

The Moving Parts Moving,

Priority One. Call Us!

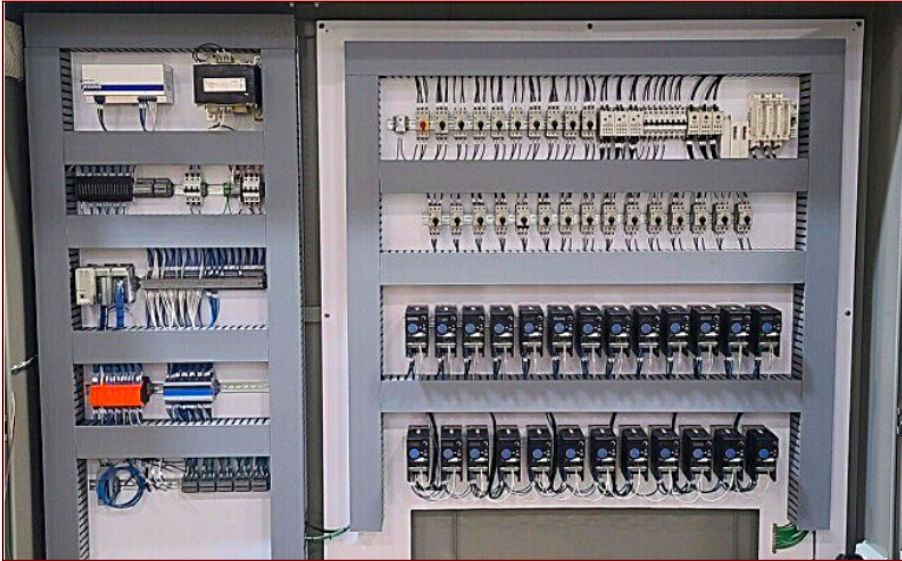

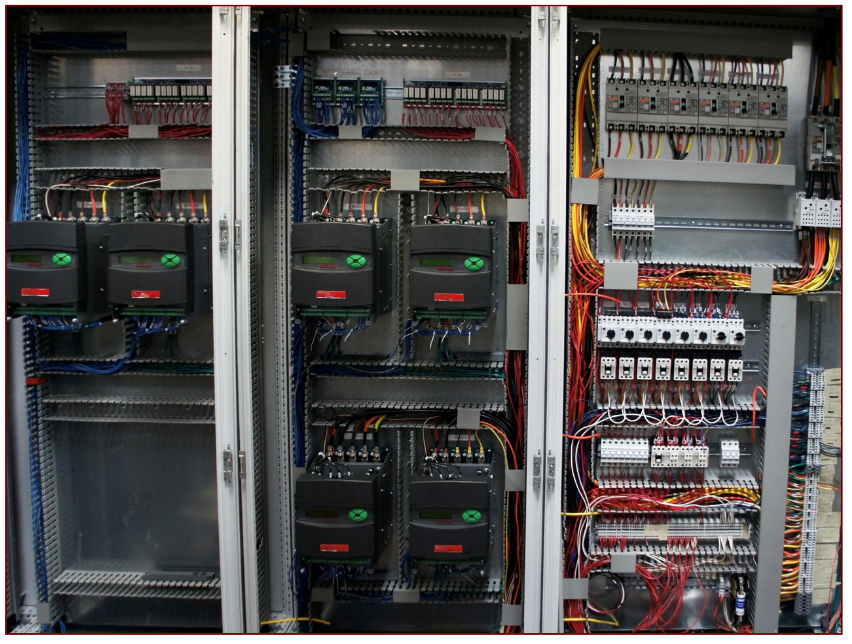

WE MAKE AUTOMATION SIMPLE

Turnkey Solutions From Design To Start-Up

TROUBLESHOOTING

PREVENTIVE MAINTENACE

EMERGENCY SERVICE

Elements of Preventive Maintenance

The following are some important functions of the preventative maintenance program:

1. Inspection or checkups

The investigation is a fundamental capability of the preventive maintenance program. Crews kept for this purpose should be well-trained. These teams compete for both external and internal inspections. External inspection means looking for and identifying defects from unusual sound, vibration, heat, and smoke. When the machine is in operation, internal inspection ensues – inspection of internal parts, for example, gears, bushes, bearings, tolerances in the parts, etc., during the time when the machine is under planned shutdowns.

2. Lubrication

Mechanical parts – gears, bearings, bushes, and other friction surfaces; offer execution for extensive stretches when deliberately greased up. Efficient lubrication is the application of lubricant at the perfect time, at the right place, and in the right amount. For lubrication, a schedule ought to be ready and followed rigorously.

3. Planning and scheduling

Each preventive maintenance must be pre-arranged in detail; based on the examination done on the past records. A scheduled program should be followed; in this manner, the program must specify the points requiring daily, weekly, monthly, half-yearly, or yearly attention.

4. Records and Analysis

Record keeping is fundamental for good preventive maintenance, as it helps in forecasting maintenance.

5. Training of maintenance staff

For the success of preventive maintenance, sound preparation is important for the maintenance personnel. Thus the professionals and supervisors are prepared to implement maintenance, inspection, and repairs deliberately.

6. Storage of spare parts

Sometimes machines stay inactive for the need for extra parts for a significant time. Accordingly, it influences extensive loss of production. Henceforth, it is essential to keep the spare parts away from loss of production.